Below is the information I’ve compiled on deleting the ABS system and converting to non-ABS brakes on a second generation J body, in my case the 93 Sunbird two door. It never worked, added weight, complication, and I just didn’t see the need for keeping it around. It cleans up the engine bay a little too.

Depending on what you think is easier, you can either take apart the ABS master cylinder and reuse it, or you can swap in a pre 92 one and use it. If you use the ABS one, you’ll have to drill and tap the lower two ports, but you can then reuse all but one of your original lines with a little bending. When drilling for tapping, don’t drill into the sealing surfaces/taper of the master cylinder or you may create sealing problems. If you use the non-ABS one, you’ll have to cut 3 of 4 lines, bubble flare them, get some new fittings, and then bend them into position.

The info below should get you started, but it can be done many different ways. You could probably find adapters to prevent doing any cutting and flaring, some people like to convert to AN lines, and so on.

I went the non-ABS master cylinder route just because I wasn’t sure what would be involved until I pulled the ABS stuff apart later on to check it out, and I already had all of the extra fittings required.

Master Cylinder Info

All fittings are metric iso bubble flares, and all lines are 3/16″.

brake locations refer to L(eft) as driver side, R(ight) as passenger, F(ront), and R(ear) brakes

mcyl locations refer to F(ront of car), R(ear of car), U(pper port), and L(ower port)

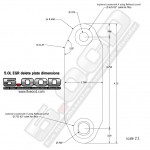

ABS mcyl sizes from left(front of car) to right(rear of car) factory:

brake location – fitting size

LF – M10 x 1.0

RR – M11 x 1.5

LR – M10 x 1.0

RF – M11 x 1.5

ABS mcyl port sizes with abs equipment removed:

brake location – fitting size – location on mcyl

LF – M10 x 1.0 – UF

RF – M10 x 1.0 – UR

RR – .314 dia. untapped – LF (tap to M11 x 1.5, drill size 9.5 mm [.374 in] to reuse stock line)

LR – .314 dia. untapped – LR (tap to M10 x 1.0, drill size 9 mm [.354 in] to reuse stock line)

Non-ABS mcyl sizes:

brake location – fitting size – location on mcyl

RR – M10 x 1.0 – LF

RF – M11 x 1.5 – UR

LF – M12 x 1.0 – UF

LR – M13 x 1.5 – LR

Brake line fittings for conversion:

brake line – if using ABS mcyl – if using non-ABS mcyl

LF – as is – to M12

RR – as is if abs mcyl tapped to M11 – to M10

LR – as is if abs mcyl tapped to M10 – to M13

RF – to M10 – as is