Research and Development Mishap.

Cracked head …

After it started acting up again and I ran a leakdown test, it shot coolant out the thermostat housing showing that number three was in bad shape. Luckily I found a place that offers remanufactured heads at a reasonable price that didn’t require a core in return to get things underway quicker. Once the old head was off, I could see cracks between the valves in all four combustion chambers. (Pics to follow.)

So after the new head all is finally well, which is good because now I need to replace the leaking rusted out fuel lines on the 2 door… it’s always something.

Hood pins.

I made a temporary hood pin that was basically a threaded rod to replace the Quik Latch ball stud and then turned up a stepped washer on the lathe to bolt the hood closed. Then I set to work on designing my own hood pins. I wanted them to function similar to the Quik Latches and not need any tools to open the hood, be quick and easy to operate, be small and unobtrusive, have a flush look unlike regular hood pins, use the same holes that were already in the hood, and most importantly be solid! Which of course is asking a lot. That being said, I think I succeeded and really like the look of the new ones with the black anodized aluminum top piece. The new pins work with ball lock pins that latch into stainless receivers mounted to the radiator support. They were a bit of a challenge to install due to getting the compound angles to line up, but once that was taken care of they worked fine. They seem very rugged, so we’ll see how they hold up in the long term.

Yet another head gasket.

The worst part was trying to get it done outside in the driveway between New England snowstorms. I spread it out over the course of a month, usually just working on it for one day out of the weekend. So in the end it only took maybe 4 days (not full ones either) and went pretty well. I bundled up, warmed my hands on a halogen light and it wasn’t too terrible. All good now…

Exhausted 2.0

- just because

- tip

- muffler

- resonator

- merge and beyond

- merge

- top of header

- flange

Wagon work 1.

Welcome, wagon.

The other thing I like about it of course is that it’s (yet another) J body, so the parts interchangeability factor will make it a lot more economical to keep up. The SOHC 1.8L is the predecessor to the 2.0L, so it’s extremely similar. In other countries they refer to them both as the big block, which I always find funny. The 2.0 is just a bored and stroked version of the 1.8, and you could actually bore the 1.8 block to 86mm like the 2.0 and convert it if you really wanted to. Anyway, the idea is for it to be a comfortable family and whatever-else hauler and probably mostly a backup vehicle if one of the other two birds need some work or whatever. I’m planning on spending the day tomorrow conquering some rust and doing some welding on it, and I’m already loving the room of the wagon, as I have the hatch filled up with 4 toolboxes, a big box full of parts and junk, and a fresh welding tank with room to spare.

Side marker upgrade.

Now for one they look better, and for two pop on and off easy with no tools. I used some standard steel hardware because it was available, but plan to replace it with nylon wing nuts and washers – they won’t rust and should hold them on just fine. I took a picture of the threaded studs, but it came out terrible so I’m not going to bother…

Bird update 9/14

On to what’s been going on…

Stage 1 performance upgrade attempt 1:

The plan was to grab a UAFC from 14point7 to do some quick and dirty tuning, put in new followers and a factory 20SEH cam, magically add 15-20hp and wind up with somewhere around 125-130hp quick, cheap, and easy! Of course reality struck soon after and the UAFC wouldn’t read the RPM and suddenly the project was dead in the water. To their credit, they were very helpful in trying to get it working, but in the end it wasn’t happening. I was not about to toss a wildly different cam into my daily driver and see what happened, so back to square one. One of the reasons I wanted to try this route is the ease of setup. I still plan to go to the Megasquirt, and now it seems to really be the only option anyway, but I need downtime to get it all set up which can be tricky on a daily. So one step at a time I’ll see if I can get the MS ready to go and then maybe I’ll need some experienced help to iron out the tuning quickly. Then toss in the new cam and see how it does. It will just take a while I’m sure, which is what I was hoping would not be the case.

In preparation for the piggyback tuner, I swapped from a DIY wideband kit which seemed to work ok, but was pretty jumpy to an AEM wideband controller & gauge mostly because it is simpler and would help with datalogging. It was an easy switch and the gauge looks and works very nice.

Painting project:

I was going to call this the beautification project, but that was kind of laughable. My friend convinced me that a rattle can paint job was the way to go, especially for how I use the car, and I think he was right. Scrapes, repairs, changes, just grab the extra can off the shelf and touch it right up … no messing around. On a whim, I changed my mind about the color – previously I’d wanted to keep it gray and really like the “cement gray” color found on some newer Scions. I still may have to use that on something down the road. Anyway, the new color of choice is Krylon italian olive satin. Love it or hate it, that’s what it is. I spent all weekend grinding some rusty spots, and acetoning off the old flaky clearcoat, and then masking and painting of course. A few things I learned along the way are:

- It is extremely difficult to get the paint to look even when using cans (a real spray gun is much easier in this respect actually.)

- Those paint-can-trigger things are very well worth it

- The roof is easily the hardest part to do and to get even (mine isn’t even, but it’s done.)

- It takes about a dozen cans (I used 10 actually, but better to be safe, and I had a nicely primed base.)

- To get it to look even kinda smooth and even takes some serious practice, if it’s possible at all … the best I can advise from my limited experience is to try broad, quick strokes, and do sections while keeping them “wet”

- Start with the roof (this tip was passed down to me.)

- There’s a fine line between sparse paint, enough paint, and a run.

Below are some pics. It’s certainly not the prettiest thing on the road, but it does look a lot better than flaking clearcoat, and I like how it turned out. I ran out of time for the additional masking needed to do the hood black so I just shot it in green, but it will be getting painted black. Also, I left the spoiler off for the same reason and moved the third brake light inside the car. I kinda like the wingless look, but nobody else I ask seems to, so I’m not sure on that one yet. I’m going to keep the brake light inside because the old metal housing was heavy and all the bolts were seized in it.

- pre paint 1

- partial paint 1

- partial paint 2

- finished paint pre reassembly

- painted, reassembled, driven to work

Stage 2 upgrade/the future:

The next big thing scheduled is getting a full stainless 2.25″ mandrel bent exhaust fabbed up with v bands at the resonator and muffler, which will be a Borla ProXS. Same one that’s on the four door and has a really nice sound without being super loud. The shop where I intend on getting it done is pretty busy, so it might be a month or so before it happens, then will try and get some pics up of it.

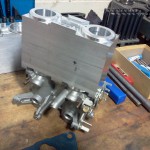

Another project that has been under wraps for quite a while is a custom individual throttle body intake setup that I’d like to use with the Megasquirt, a ported head, stainless header, Newman cam, and rebuilt engine. This is the Stage 2 plan. It took a ton of time to model and machine the intake, but it is basically finished now. Internally, the runners taper from the size of the tb outlets to the intake runner port size, while bending between the spacing of the tbs and the runners. The throttle bodies are from a GSXR600. I still need to do some work to attach the throttle shafts back together, the fuel rail, updated clamps to hold the bodies to the intake, and some other minor stuff. I also designed some intake trumpets and retainers and had them 3d printed. I’m not sure if I’m going to use them yet – mostly because there are no provisions for filters, but it was a fun process regardless. The throttle bodies originally have 2 injector ports per runner and secondary butterflies, so I had to make some plugs for the extra holes after removing everything. Also, had the injectors tested and kept the 24# set, which should be perfect. I began some port work to the head by opening up the intake runners at the valve seats, but have stalled on head work for now because of time. Here are a few mockup pictures of the intake in progress, and that’s it for now.